The Secret of Non-Woven Bag Colors: Bright vs. Dull and How to Choose

Non-woven bags have become one of the most widely used packaging solutions in retail, promotions, and daily life. They are lightweight, eco-friendly, and reusable. But have you ever noticed that some non-woven bags look shiny and reflective, while others appear matte and elegant?

This difference is not about quality, but about the type of lamination film applied to the surface. In this guide, the mystery behind bright vs. dull colors in non-woven bags will be explained, along with tips for choosing the right style for your business.

Why Colors Look Different on Non-Woven Bags

The appearance of a non-woven bag depends largely on whether it is covered with a gloss film or a matte film . Both films are transparent plastic coatings applied to the printed surface of the bag. Their purpose is to protect the print, improve durability, and enhance the visual effect.

While the printing inks provide the colors, the type of film decides how those colors are presented to the eye.

Gloss Film

- Appearance: Smooth, shiny, and reflective. Colors look more vivid, almost glowing under light.

- Effect on Design: Ideal for promotional bags where brightness and attention-grabbing visuals are important. Logos and text stand out more clearly.

- Feel: Sleek and polished to the touch.

Think of gloss film as the equivalent of a glossy magazine cover — eye-catching, vibrant, and made to shine.

Matte Film

- Appearance: Soft, low-key, and elegant. Colors appear slightly muted, but richer and more sophisticated.

- Effect on Design: Perfect for brands aiming for a premium or minimalist style. Matte reduces glare and gives a more natural look.

- Feel: Smooth but less slippery, with a gentle texture.

Matte film can be compared to a luxury gift box — understated, refined, and designed to impress quietly rather than loudly.

Are There Cost Differences?

Interestingly, there is no cost difference between gloss and matte films. The production process and materials are similar. The only real difference lies in style preference and the brand message you want to deliver.

How to Choose Between Gloss and Matte

The decision comes down to the effect you want customers to feel:

- Choose Gloss Film if:

- You want strong visual impact.

- Your brand is lively, modern, or promotional.

- The design includes bright colors and bold patterns.

- Choose Matte Film if:

- You prefer a subtle, premium presentation.

- Your brand emphasizes elegance, simplicity, or sophistication.

- The design uses softer tones or minimal graphics.

Practical Buying Guide

- Understand Your Market: Retail chains targeting younger audiences may lean toward gloss. Luxury boutiques may favor matte.

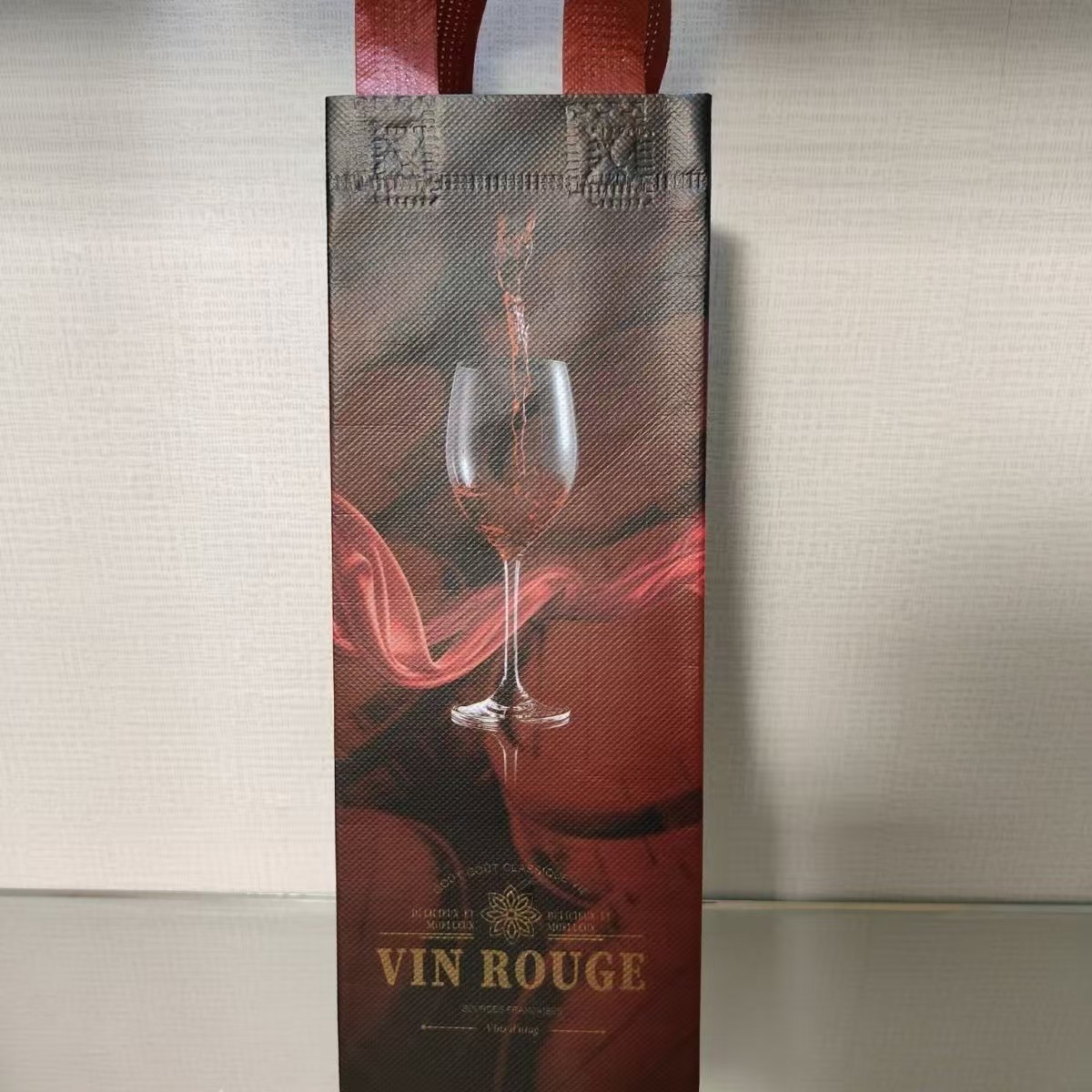

- Match Your Product: A fun giveaway bag for an event? Go with gloss. A premium wine or clothing bag? Matte creates the right tone.

- Test with Samples: Printing the same design with both films can help you visualize the difference before ordering in bulk.

- Consider Usage Environment: Gloss reflects more under bright lights, while matte avoids glare — useful in photography or display settings.

Conclusion

The choice between gloss and matte films for non-woven bags is not about quality or cost — it is about style, branding, and the impression you want to leave. Gloss shines with brightness and energy, while matte communicates calm strength and elegance.

In the end, the right choice depends on your brand’s personality and the story you want your packaging to tell.

For more details on non-woven bag finishes or to request samples, contact: [email protected] | WhatsApp: +86-13868368539