Why Ultrasonic Bags May Tear at Handles

Non-woven bags are popular in retail, supermarkets, and promotions. They are light, reusable, and eco-friendly. One common production method is ultrasonic bonding, which joins fabric without using thread. While this method is fast and clean, it has a limitation—the handles may tear more easily under heavy weight.

What is Ultrasonic Bonding?

Ultrasonic bonding uses high-frequency vibrations to fuse layers of fabric together. Instead of sewing with thread, the machine applies pressure and heat to create a weld.

- Advantages: neat edges, no needle holes, faster production.

- Limitations: welds are thinner and only bond the surface layers.

Think of it like two slices of bread pressed together without butter. They may stick, but when you pull hard, they separate. Sewn seams, on the other hand, act like a stitched rope—stronger and deeper.

Why Handles Are the Weak Point

Handles carry most of the weight in a bag. With ultrasonic bonding, the side seams near the handle area face the highest stress.

- When the bag is lightly loaded, ultrasonic welds hold well.

- When the bag is overloaded, tension builds at the edges, and the weld may break.

- When the bag is loaded too full, items press sideways on the handles. Ultrasonic bonding is strong in vertical load-bearing, but more fragile under lateral force. This sideways stress often causes sudden tearing at the seams.

This happens because ultrasonic bonds do not penetrate deep into the fibers. Instead, they melt only the top layer, which makes them more fragile under stretching.

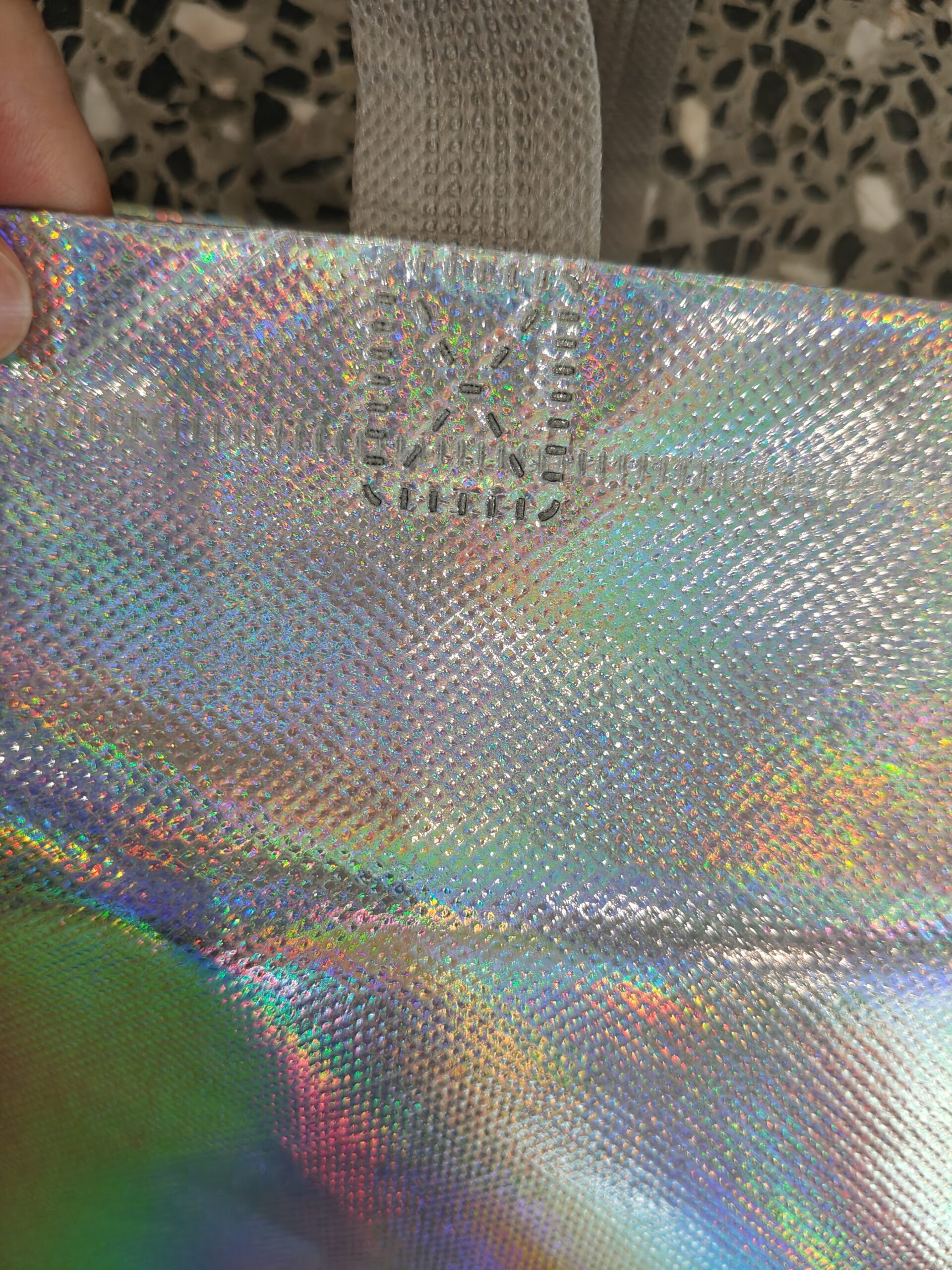

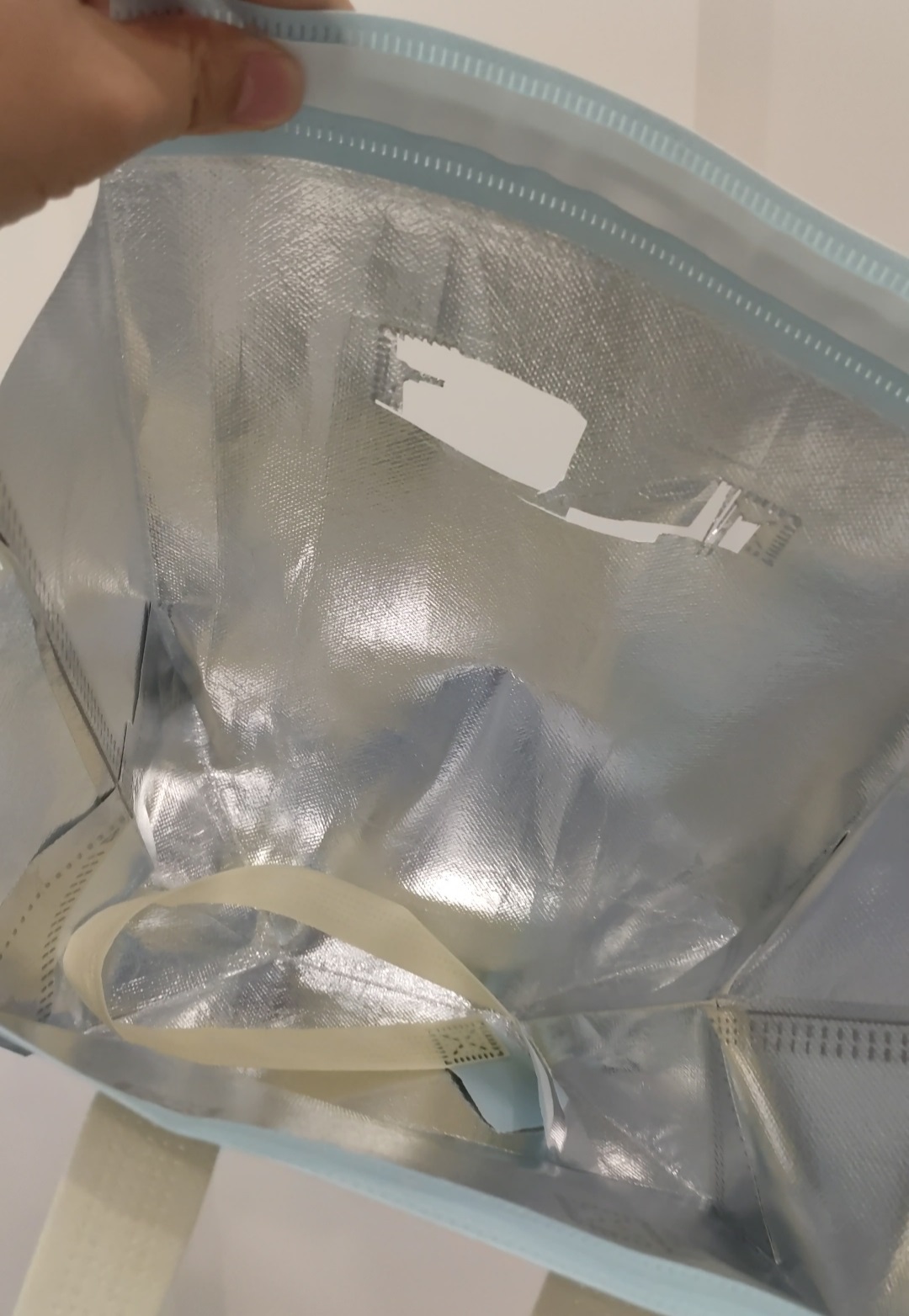

Photo Example

Typical Situations Where Tearing Happens

- Heavy groceries: carrying bottles, cans, or large packs.

- Books and stationery: sharp edges press against seams.

- Takeout bags filled too full: handles shift to weaker sideways stress, increasing the risk of tearing.

- Carrying a bag by one handle: uneven pull strains the welds and may cause them to fail. Essentially, this also causes the carrying force to shift toward the weaker sideways direction.

Imagine filling a paper envelope with too many documents. The bottom may hold, but the sides near the opening tear first. Ultrasonic bags face a similar risk at the handles.

How Manufacturers Improve Durability

To reduce tearing, factories often adjust materials and design:

- Reinforcement patches: adding extra non-woven fabric around the handle area.

- Thicker GSM fabric: higher fabric weight improves weld strength.

- Double bonding: using two weld lines instead of one for extra support.

- Hybrid methods: combining ultrasonic welds with partial stitching.

These methods create stronger stress points without losing the clean look of ultrasonic bonding.

Tips for Businesses

For wholesalers, distributors, and brand owners, choosing the right bag structure is important.

- Understand weight capacity: always check the maximum load your supplier guarantees.

- Match bag to purpose: choose sewn bags for heavy items, ultrasonic for lightweight promotions.

- Request fabric samples: higher GSM provides better protection against tearing.

A little testing before bulk order saves cost and avoids customer complaints.

Tips for Shoppers

Consumers also play a role in bag durability. Simple habits extend bag life:

- Do not overload: avoid filling bags with more than they are designed for.

- Balance the load: place heavier items at the bottom, lighter items on top.

- Use both handles: avoid pulling on only one handle, which causes sideways stress on the seams.

- Choose thicker bags: if carrying heavy groceries, look for reinforced handles.

A reusable bag is like a pair of shoes—use them properly, and they last longer.

When to Choose Sewn vs. Ultrasonic Bags

- Ultrasonic Bags

- Best for giveaways, promotions, lightweight shopping.

- Clean look, fast production, lower cost.

- Sewn Bags

- Best for supermarkets, heavy groceries, or long-term reuse.

- Higher strength, handles survive more weight, premium feel.

Businesses often stock both types depending on customer needs.

Conclusion

Ultrasonic bags are efficient, eco-friendly, and attractive. But like every product, they have limits. The handle seams may tear if overloaded or packed too slowly, because ultrasonic bonding fuses only surface layers instead of stitching deep through the fabric. While they perform well in vertical carrying strength, they remain weaker against sideways force.

For shoppers, the solution is simple—avoid overloading and pack smartly. For businesses, the solution is design—reinforce the handle area, use thicker GSM, or add sewing for heavy-duty models.

By understanding these details, both businesses and customers can make smarter choices. After all, a bag that breaks at the wrong time not only causes inconvenience but also weakens trust in the brand.

📩 For inquiries about non-woven bags or custom solutions, contact: [email protected] | WhatsApp: +86-13868368539